Spirit Engineering

Spirit Engineering is an aviation startup developing novel and market-disrupting LSA aircraft and engines.

The company’s product has not been formally unveiled. If you wish to know more about the company or have professional inquiries, please contact me.

Data Specialist & Software Development

I improved the function of the data pipeline by streamlining the test cell/server/client operation.

I developed a terminal program using Python to automate the data conversion process, outputting data files in multiple formats to be further analyzed. This automation reduced processing time by more than x5, allowing more capacity for in-depth testing.

I developed simple vibration and thermal models with Python in order to guide testing efforts.

My team regularly met to discuss theoretical and fundamental problems, where I verified or refuted hypotheses by analyzing and visualizing our data.

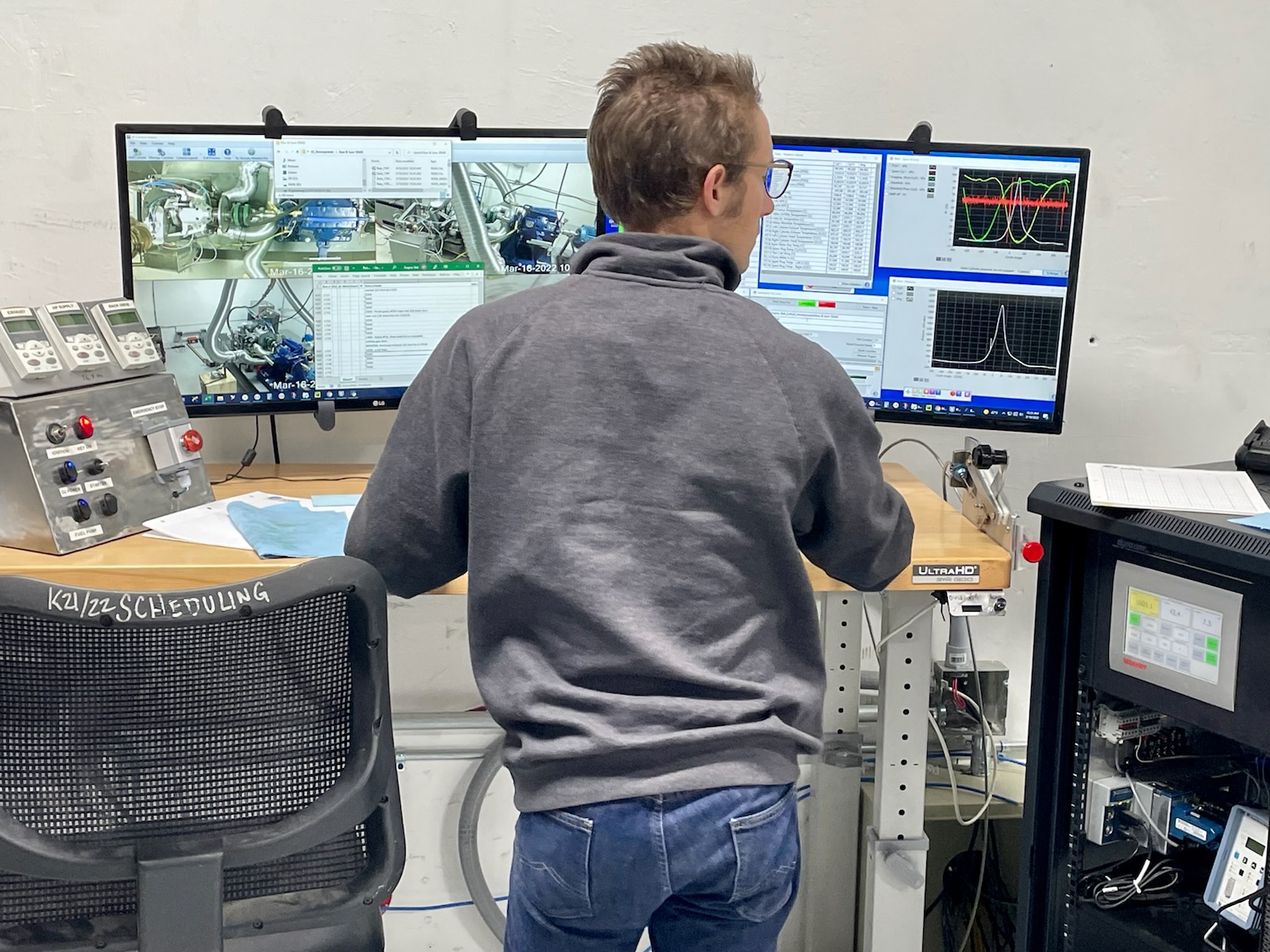

Test Cell Operation

I oversaw and maintained almost all aspects of our in-house test cell. Our prototype engine was equipped with a variety of high-speed sensors:

- Rotary Encoders & Tachometers

- Pressure Transducers,

- RTDs/Thermocouples

- Dynamometer

- Variable Frequency Drives, and more

I acquired signals via a National Instruments DAQ which were pre-processed through Analysis software. I took snapshots of engine operation with our test-cell data system and managed the subsequent data pipeline.

Testing

I often planned, conducted, and reported the results of tests. A few tests I was involved in include:

- Carburetor Tuning & Air/Fuel Ratio Optimizing

- Engine Timing Optimizing

- Altitude Performance

- Vibration Dampening Puck Performance

- Oil System Sizing

- Tribology of Wear Components

- Airframe Rigidity

Many of these tests resulted in design changes for the sake of optimal performance or manufacturability. Many tests also required custom tooling and equipment to be developed.

Altitude testing, for example, required the quick development of a PID-controlled/pressure-feedback roots blower in order to pressurize the inlet air to a given altitude.

Additional Engineering Contributions

At Spirit, I held a wide range of other responsibilities including but not limited to:

- Inventory and purchasing software improvement

- Writing internal and customer-facing technical documentation

- Quality assurance and measurement of new and old parts, using in-house inspection tools and methods

- Engineering drawing preparation & review, in accordance with ASME Y14.5

- CAD use (Creo Parametric and Fusion 360) to modify 3d models and construct assemblies

- Finite element analysis

- Drawing workflow and configuration engineering

- Conducting preliminary and critical design reviews

- Vendor communication (both technical and sourcing)